CAPABILITIES

Today we manufacture Electro-Mechanical critical components, these components have been used in commercial, cargo, military aircraft, hybrid vehicles and medical.

Manufacturing capacity 10,000 sq. ft. in operations and 5,000 sq ft ready for new projects

As a custom contract manufacturer building by print, We have the capability manufacturing from simple coil to rotor assemblies or complete motors.

ELECTRO-MECHANICAL

OUR CAPABILITY IS DEMONSTRATED BY THE QUALITY OF OUR PRODUCTS.

- Stator

- Armatures

- Rotors

- Field coil

- Generators

- AC/DC motors

- Linear actuators

- Hydraulics pumps

- Starter generators

- Brake coil

- Rheostat

- Varistor

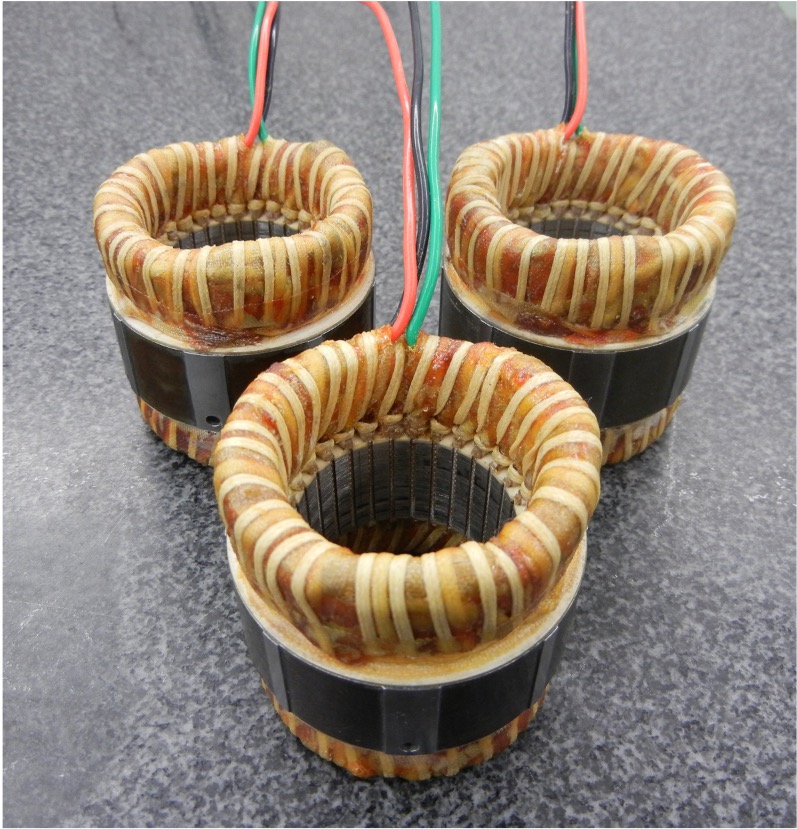

- Inductors

- Servo motors

- Brushed/brushless motor

- Rotary actuators

- Fly control actuators

Performing special processes to our products like coatings, bonding, impregnation (vacuum & trickle), epoxy encapsulation, dynamic balancing, torch brazing, soldering and fluidize bed coating.

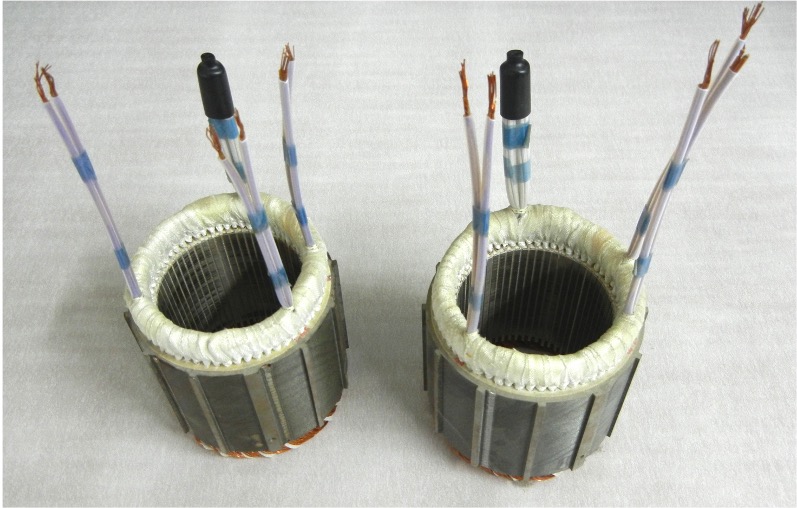

STATORS

Lamination bonding for stators, armatures and rotors cores using:

- Electric epoxy resins

- Epoxy resins with hardeners

- Rivet fastening systems

- Tig welding

- Torch welding

Build custom stator assemblies from 0.5″ to 36″

Connection soldering per IPC-J-STD-001/Space addendum, torch brazing for BCuP applications, spot welding for armatures from commutator diameters 1.000” to 5.000”.

Impregnation of stators coils using the dip & bake system, trickle impregnation.

Epoxy encapsulation using custom made retaining molds for stators.

Connection soldering per IPC-J-STD-001/Space addendum, torch brazing for BCuP applications, spot welding for armatures from commutator diameters 1.000” to 5.000”.

Impregnation of stators coils using the dip & bake system, trickle impregnation.

Epoxy encapsulation using custom made retaining molds for stators.

Working core diameter from 0.713” to 15.000” and height from 0.480” to 9.500”

Insulation systems consist of the use of fiber glass, melamine, Nomex, Kapton, Mylar insulation materials. Application of electrical resins using fluidized bed system

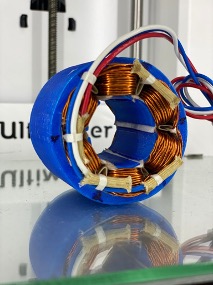

Winding and magnet wire insertion

- From AWG 42.5 to AWG 8 magnet wire

- Coil winding configurations of 2 phase, 3 phase, 2 phase + 1 phase inverted rotation

- Hairpin wire winding

- Single wire turn by turn handmade for specific stators and armatures

- Coil group winding machine

- Brake coil winding machine

- Rheostat/Potentiometer used for aerospace dashboards

Lead wires connection and lacing of end turn coils.

Connection soldering per IPC-J-STD-001/Space addendum, torch brazing for BCuP applications, spot welding for armatures from commutator diameters 1.000” to 5.000”.

Impregnation of stators coils using the dip & bake system, trickle impregnation.

Epoxy encapsulation using custom made retaining molds for stators.

ROTORS

- Lamination stacking with copper bars and copper or brass end rings.

- Aluminum and copper castings rotors.

- Installation of shafts into rotors and machining of the assembly.

- Dynamic balancing of armatures and rotor/shaft assemblies.

TECHNICAL DATA

Stators currently build are being used on aircraft landing, hydraulic, cooling and fuel systems and some technical data is:

3 phase winding

Input: 115/200 VAC 400 Hz

Output: 69 lb/in @ 7600 RPM

86 lb/in @ 5600 RPM

7.5 hp @ 7600 RPM

24-28 AMPS

MACHINING SERVICES

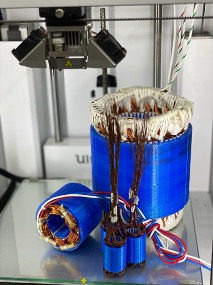

Reverse Engineering Capability + R&D support for current and new products or prototypes.

When no drawings exist, ELM AEROSPACE can deconstruct an existing part sample to re-engineer a design solution and create the necessary manufacturing prints and documents to support future part production.

We are always working on the edge of what’s technologically possible. This includes using 3Dprinting. We can help you visualize your products with concept model, create rapid prototypes to shorten product development cycles.

We have the capability from simple coil to a complex critical components.

Manufacture of stators, exciters, rotors, armatures, brake coils, field coils, capacitors, varistors, rheostats, wiring harness, inductors for fuel pumps, generators, fan motors, actuators, landing gears and hydraulics.

Performing special processes to our products like coatings, bonding, impregnation (vacuum & trickle), epoxy encapsulation, dynamic balancing, torch brazing, soldering and fluidize bed coating.